Car factories are shutting down and customers don’t get the mobile phone they want. The whole world notes that there is a shortage of microchips.

An unknown number of popular songs claim that “love makes the world go round”. The updated version could be about microchips. Small electronic parts are in everything from toasters to space rockets.

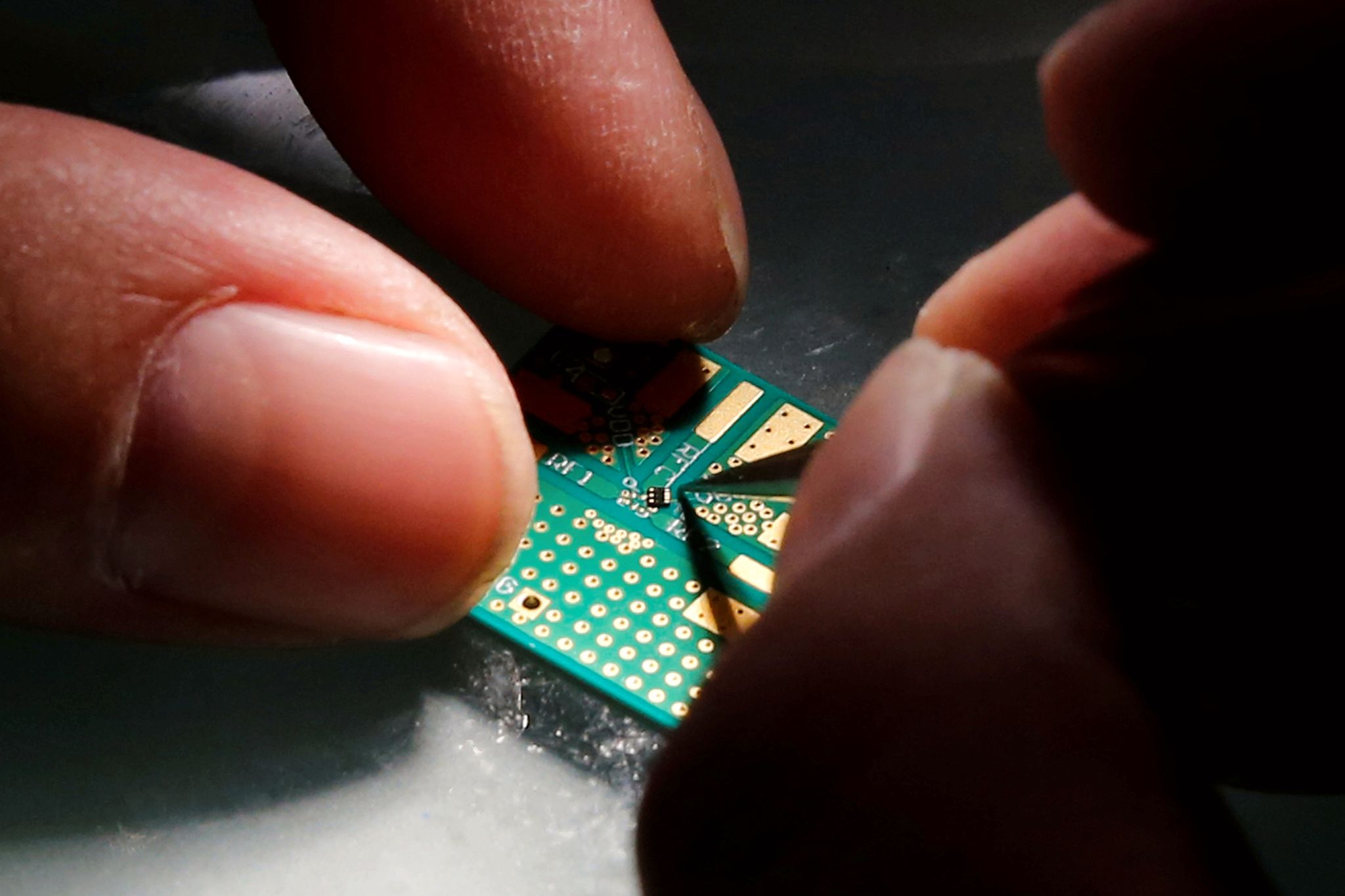

Without them, most things around us would stop. Cars, phones, bank cards, and home electronics stop working without the chip, which is often smaller than a fingernail.

In the past year, the lack of microchips has led to major problems.

On Thursday, it was announced that Toyota, the world’s largest automaker, would cut production in September by 40 percent. Instead of 900,000 new cars, they are satisfied with a production of 540,000, according to the BBC.

Volvo’s plant in Ghent, Belgium, halted production for three days this week. 5,000 workers were sent home. In June, British car production was at the same level as in 1953.

Sony announced that the lack of chips is affecting the production of the PlayStation. Apple fears delays in the production of phones.

What is causing the problem?

The most common explanation is coronary artery disease. Most of the chip factories are located in Asia. Many of them were closed for a long time when the epidemic was at its most severe.

At first, it seemed like the pandemic would significantly reduce people’s willingness to buy. Therefore, production was reduced. When it turned out that customers were more than happy with their shopping, there really was a shortage of chips.

But even before the world heard about COVID-19, there was a shortage of microchips, according to her popular science. Demand is rising sharply.

Weak relations between China and the West also contribute negatively.

The Chinese are major consumers of microchips. But they don’t have any big production themselves. The United States prohibits the export of technology to China, as it is considered defensively sensitive. Therefore, China is struggling to create its own production. The result is that they are competing for the same chips as Western factories.

technology site Edge Markets He thinks there may also be talk of manufacturers manipulating the market. The battle over available microchips has driven prices up dramatically. So far there is no evidence for this suspicion.

How is people’s daily lives affected?

In July Aftenposten reported on Bjorn Haakon Rognog still waiting for the car he ordered in October of last year. It’s basically finished, except that it lacks ‘mind’. The Skoda factory is waiting for microchips for its cars.

The problem is even bigger in the auto industry. But it is spreading to many other industries. Apple and Samsung warned early on that they might have problems.

Customers who receive their merchandise must find themselves paying more for it.

Read also

A little piece stands between Bjørn Håkon Rognhaug and his new car

What is the industry doing to solve the problem?

In the United States and Europe, both politicians and industry leaders are talking about the need to reduce dependence on Asia. Today, 70 to 80 percent of the world’s microchips are made in Taiwan and South Korea.

Building new factories is a huge investment. It requires billions of dollars. One must also train the workforce. At best, it may take two years to set up a factory.

Small chips are big policy. In April, US President Joe Biden invited business leaders to a meeting at the White House. He also participated in the National Security Council.

“The semiconductor shortage, which is affecting American workers and families today, is the highest priority for the president and his top advisors,” the White House wrote in a statement. press release.

At the meeting, they discussed what it would take to increase production in the United States. Even with political will and risk-averse investors, it will take many years before US production becomes large enough to truly pay off.

How long can it last?

At the end of July, Pat Gelsinger said BBC That the situation may become more difficult. As the CEO of Intel, he knows what he’s talking about. Intel has for many years been the dominant supplier of equipment to the IT industry.

He stressed that the West should try to improve cooperation with China.

At the same time, new plants must be built both in the United States and in Europe. But it will take several years.

Reuters Talk to leaders in the auto industry. They also expect the crisis to continue for some time until 2022.

“Web specialist. Lifelong zombie maven. Coffee ninja. Hipster-friendly analyst.”