Humid air and low temperatures are a dangerous combination near wind turbines. Ice forms on turbine blades, and this icing has at least three unfortunate consequences.

Even thin layers of ice create an imbalance in the system, which in turn increases the risk of damage and results in higher repair and maintenance costs for the operator.

Under unfavorable conditions, turbines must be stopped, resulting in loss of income. The last and most dangerous consequence is the danger of ice floes. Wind turbines can shed ice blocks weighing up to 15 kg.

Huge losses

The loss of income from lost production when an icing hazard causes wind turbines to shut down is significant. TU was not able to get an overview of the exact size of the project, but a rough estimate says at least NOK 200,000 per turbine per year.

– maybe more. Then I calculated using a medium-sized turbine at a Norwegian wind farm, that icing causes a loss of three percent of production, at 50 euros per kilowatt-hour, says project manager Daniel Flo, at Stormvind, a wind power consultancy. .

He adds that the price quickly becomes higher than 50 euros in the winter.

Today, turbine suppliers offer systems to prevent icing. These use heating, which is very expensive. The price is so high that very few people install such facilities on Norwegian wind farms, says Flo.

This means that our 1,392 wind turbines lose electricity production worth NOK 278 million over the course of the year. Hence the costs of dealing with ice formation are not included.

He can throw ice 400 metres

For humans, an impact energy of 40 joules or more is considered dangerous. This means that small blocks of ice weighing up to 100 grams can cause serious damage. This is what Øyvind Birkjedal at Norconsult told TU in 2020.

NVE has calculated where the 18 wind turbines at Tonstad in Sirdal municipality could throw chunks of ice at a height of 406.5 metres.

Now the ice problem can move toward a solution. Behind it lies expertise in automated industrial spray coatings, advanced and precise drones, and a mixture of urea, formerly called urea, and wax.

Sprinkle on a thin layer

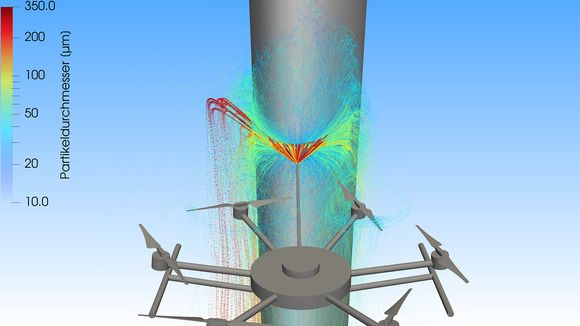

Researchers at the Fraunhofer-Institut für Fertigungstechnik und Angewandte Materialforschung and the Fraunhofer-Institut für Produktionstechnik und Automatisierung have developed a joint solution in which a thin layer is sprayed on the blades – a layer that prevents icing.

Their first challenge was to develop an agent that was environmentally friendly, adhered properly to leaves, and remained in place for several weeks. The result was a mixture of urea, also called urea, and wax. The mixture developed must have good adhesion and be resistant to cracking and peeling.

The application is carried out with the help of drones equipped with components of synthetic paint. At high pressure, the mixture is pumped through a long, thin tube. At the end there is a nozzle with a 0.3 mm opening. The system pumps the entire mixture without air, and allows the spraying of small droplets with a diameter of only 0.1 mm. The system must be usable in wind speeds up to 9.7 m/s, which corresponds to refreshing breezes of 8 to 10.7 m/s.

Manufacturing and production

In an article on the Fraunhofer website, Dr. Oliver Tiedge says that they relied on achieving high precision, among other things, because it is very important to cover the edges of the rotating mixers with a thin layer of wax and urea.

– Years of experience in modeling processes have helped us achieve efficient dissolution and optimal droplet size, says Tidge.

The Fraunhofer Institute writes on its website that the results are now so good, so far, that the next step is to join forces with industrial partners and develop a product that can be produced on a large scale. In the project called Turbo, there are 19 companies in the fields of paints, raw materials, drone manufacturers and wind energy companies.

Wind energy in Norway

In the proposal for a ground rent tax on wind energy, the government refers to figures from the NVE and writes that in April this year there were 65 ground-based wind power plants in Norway with a total of 1,392 wind turbines. The installed capacity reached 5,083 megawatts, and the normal annual production is 16.9 terawatt hours, which is equivalent to 11 percent of our total electricity production.

“Web specialist. Lifelong zombie maven. Coffee ninja. Hipster-friendly analyst.”